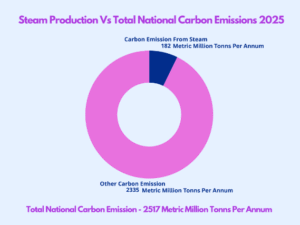

Steam may seem mundane, but it sits at the heart of modern manufacturing. From food processing to petrochemicals, textiles to pharmaceuticals, steam is the hidden engine that powers production lines. And as India seeks to accelerate its march toward becoming a developed economy, steam is expected to play an even larger role. That dependence comes with a price. Steam production today accounts for nearly a quarter of India’s industrial carbon emissions—182 million metric tons annually, out of a national total of 2,517 million. Unless urgent steps are taken to clean up how it is generated, this overlooked source of emissions could undermine India’s climate goals, including its pledge to reach net zero by 2070.

The scale of the challenge is sobering. To achieve the government’s vision of ‘Viksit Bharat’—a developed India by 2047—the economy must expand to $26–30 trillion. That in turn requires manufacturing to grow five- to six-fold, since it contributes about a quarter of GDP. A recent study estimates that such growth would demand a fourfold increase in steam generation. Even under more modest growth trajectories, steam output would still need to double from today’s 1,263 million metric tons.

The numbers point to a stark truth: without transforming the way it produces industrial steam, India risks locking itself into a future of rising emissions just as the world demands reductions. Cleaning up this overlooked corner of industry is not just an environmental imperative—it is an economic one.

Steam’s Heavy Carbon Cost:

A new study by the non-profit iForest, released in May, has laid bare the scale of India’s steam problem. Led by Chandra Bhushan, the team compiled existing data to produce the country’s first-ever survey of industrial process boilers—the workhorses behind steam generation. Their conclusion: steam accounts for a staggering 182 million metric tons of carbon emissions each year.

India cannot afford to follow the same polluting trajectory that first powered Western industrialization and later fuelled China’s rise. As a signatory to the Paris Climate Accord, New Delhi has pledged a sustainable development path. That makes cleaning up the steam boiler sector not optional, but essential.

The government seems aware of the challenge. “The evolving industrial landscape necessitates a transition towards more sustainable and efficient practices. This will essentially translate into phasing out aged boilers and the introduction of a green fuel mix for them in order to keep carbon emissions in check”, said Sandeep Kumbhar, secretary in the Ministry of Industry and Commerce.

The numbers underline the urgency. Out of the 600 million metric tons of carbon dioxide emitted annually by Indian industry, nearly one-third comes from steam. According to the International Energy Agency data, with total national emissions at 2,517 million metric tons in 2022, steam alone is already a significant contributor. If steam demand were to quadruple under the government’s ‘Viksit Bharat’ vision, emissions from boilers could soar past 700 million metric tons—an outcome wholly incompatible with India’s net-zero commitments.

The burden is also uneven: five states account for nearly half of these emissions, concentrating both the problem and the opportunity for solutions.

No Central Record, Big Carbon Cost:

One of the starkest findings of the iForest study is not just how polluting India’s steam boilers are—but how little is known about them. There is no centralized, digital database of industrial boilers in the country. Based on on-the-ground data from 16 states and union territories, iForest estimates that India operates roughly 45,000 process boilers, with eight states accounting for two-thirds of the total. Gujarat, Maharashtra, Tamil Nadu, Andhra Pradesh and Uttar Pradesh lead the pack, and not coincidentally, are also among the nation’s top polluters.

Food processing and chemicals dominate steam-related emissions, with the food sector responsible for the highest particulate matter output. On average, India’s boilers are 18 years old, with one in five older than 20. That age profile is troubling—not only for safety, but also for efficiency. As boilers age, their fuel efficiency declines, leading to higher greenhouse gas emissions.

The consequences are already visible. The boiler industry emits 520 kilotonnes of particulate matter, 595 kilotonnes of sulphur dioxide and 516 kilotonnes of nitrogen oxides each year, in addition to carbon dioxide. While the food industry produces more steam, the chemical sector emerges as the biggest carbon emitter, owing to its heavy dependence on fossil fuels. Sugar mills, by contrast, rely more on biomass.

The Fuel Mix and the Fix:

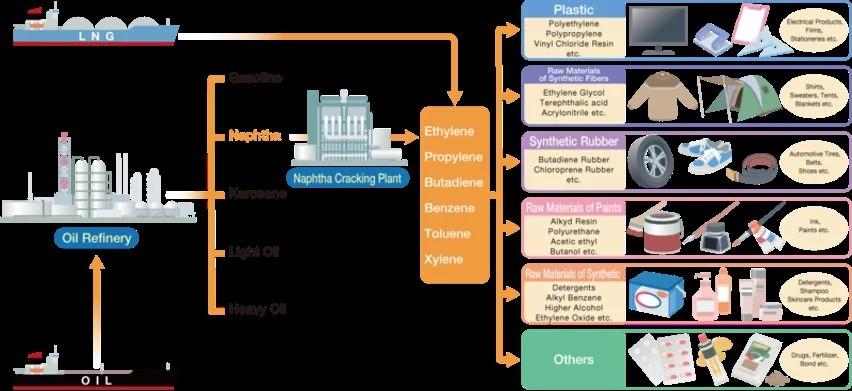

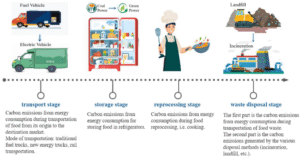

Nearly half of India’s steam is generated from biomass, including bagasse, while fossil fuels—coal, oil and piped natural gas—account for 44 percent. Process steam generation is responsible for 25 per cent of fossil-fuel based industrial emissions and 6% of India’s overall fossil fuel emissions. Steam used for industrial processes like heating, drying, pulping, evaporation, cleaning and distillation is known as process steam as opposed to steam used for power generation.

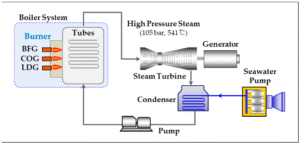

According to the iForest study, India has an extensive stock of boilers including process and co-generation (co-gen) or combine heat and power (CHP) boilers. In the case of CHP boilers, only a part of the steam is utilised in process while the rest is used for generating electricity.

Mr. Vivek Verma, founder and Managing Director of Spray Engineering Devices Ltd, (SEDL), says, “India should move decisively to phase out fossil fuel and biomass-burning boilers. The future lies in renewable electrical energy, by using it directly or via heat pumps, we can finally replace fossil fuels as our energy source.” He added, “Electric boilers, hydrogen systems, and emerging technologies can transform this sector. They are cleaner, safer, and more efficient, and will help India align with its net zero goals while improving long-term competitiveness.”

To curb this toll, iForest has outlined a four-pronged strategy: phasing out aging boilers, mandating energy efficiency standards, switching to cleaner fuels, and building a comprehensive regulatory framework. Retrofits such as heat recovery systems, economizers and efficient combustion controls can reduce fuel consumption and emissions. The report also calls for mandatory efficiency ratings and labelling for all new boilers, alongside the creation of a centralized boiler database to enable monitoring and enforcement.

Innovation and New Models:

To improve energy efficiency the report recommends retrofitting old boilers with low thermal efficiency with suitable technologies like heat recovery systems, economisers and efficient combustion controls can reduce fuel consumption and resulting emissions. The government should promote an efficiency market and institute mandatory boiler efficiency rating and labelling programmes for all new boilers. But above all it has recommended the creation of a centralised database to help monitor the process boiler sector.

Further, the report recommended expansion of research and development (R&D) efforts on emerging technologies such as high-energy efficiency super-critical boilers, electric boilers, hydrogen boilers and electric heat pumps for medium temperature applications like food, pharmaceuticals and textiles. It also recommended the introduction of community boilers and steam-as-a-service (SaaS), for faster transition.

Explaining the concept of SaaS, Sanjiv K. Kanchan of iForest described it as a shared utility model where MSMEs in a cluster source steam from a centralized boiler operated by a third party or the industry community instead of their own small, often inefficient and polluting boilers. “Centralized boilers are typically more efficient, technologically advanced and capable of using cleaner fuels with superior pollution control systems,” explained Sanjiv K. Kanchan, director of ESG & Industry at iForest. MSMEs. He added, faced with both resource and skill constraints but together operate a large number of boilers.

Beyond Safety: A Call for New Laws

Kanchan also criticized the Boiler Act of 2025 for being too narrowly focused on safety and certification. A truly modern regulatory framework, he argued, must expand to cover efficiency, pollution monitoring, governance reforms, a consolidated database of IBR non-IBR boilers, adoption of cleaner fuels and emerging models such as Steam-as-a-Service.

The challenge is formidable. Stronger air pollution norms and enforcement mechanisms are essential if the sector is to align with India’s net-zero ambitions. Achieving near-zero emissions from steam production will require not only new technology, but decisive policy, rigorous enforcement and financial support for industry. Achieving a full transition to near-zero emissions, however, will depend on how decisively and effectively the sector’s decarbonization roadmap is pursued in alignment with India’s broader net-zero pathway. Without it, India risks allowing one of its most invisible but consequential sources of pollution to undermine its climate commitments.